REGUPOL ANTI-SLIP CARGO MATS: safe transportation of heavy goods

TRUCKS | UTES | RAIL WAGONS | AEROPLANES | SHIPS

REGUPOL anti-slip cargo mats are specially designed to keep heavy goods secure, especially during hazardous events such as emergency braking; taking evasive action or travelling over irregular surfaces. The mats prevent goods from slipping while being transported on trucks, utes, ships, planes and trains. Quality mats are essential for any professional transportation company as they reduce the total pre-stressing tension required to tie down the load. REGUPOL rubber fiber mats are ideal for repeated use with sharp edged cargo, heavy goods and palletised loads. Being highly porous, the mats are capable of absorbing moisture or residue, which prevents any notable loss in sliding friction co-efficient.

REGUPOL ANTI-SLIP CARGO MATS: safe transportation of heavy goods

TRUCKS | UTES | RAIL WAGONS | AEROPLANES | SHIPSREGUPOL anti-slip cargo mats are specially designed to keep heavy goods secure, especially during hazardous events such as emergency braking; taking evasive action or travelling over irregular surfaces. The mats prevent goods from slipping while being transported on trucks, utes, ships, planes and trains. Quality mats are essential for any professional transportation company as they reduce the total pre-stressing tension required to tie down the load. REGUPOL rubber fiber mats are ideal for repeated use with sharp edged cargo, heavy goods and palletised loads. Being highly porous, the mats are capable of absorbing moisture or residue, which prevents any notable loss in sliding friction co-efficient.

ENQUIRE ABOUT THIS PRODUCT

ARE YOU AWARE OF YOUR LEGAL OBLIGATIONS WHEN IT COMES TO LOAD RESTRAINT?

Read our informative article. Understand the basic legal requirements surrounding transport load restraint in Australia. Learn the ‘Chain of Responsibility’ and the fundamental mechanisms involved in restraining cargo. Learn more…

CHOOSE A SPECIFIC TRANSPORTATION MAT

Excellent value

Ideal for medium weight cargo (up to 250 t/m2)

Most popular REGUPOL cargo mat

Designed to avoid discolouration of stain-susceptible goods

Can take higher loads than 7210® (up to 350 t/m2)

Suitable for broader range of applications

Can be used in extreme weather conditions

REGUPOL's most heavy-duty cargo mat (for loads up to 630 t/m2)

High degree of flexibility with regards to possible applications

Protects tensioning belts

Increases and compensates tension belt force distribution

Adapts the belt optimally to the load edges

4 Individual Products Available

Economical and high performance options available, ranging from 8mm-12mm with other thicknesses available on request.

Anti-slip Rubber Fibres

This is especially important for loads that cannot handle high contact pressure or high traction force. The mats help to create a unified unit with the loading surface.

Porous

The highly porous properties of REGUPOL transport mats allow absorption of moisture & residue meaning anti-slip qualities are not compromised.

Sheet or Roll Format

REGUPOL transport mats are conveniently available in sheet or roll format and can be cut to size on request.

Extreme Temperature Resistance

REGUPOL transport mats can withstand extreme temperatures of -40 °C to +120 °C.

Long Service life

REGUPOL transport mats offer a longer service life due to their material composition. They can withstand repeated use.

Suitable for a Whole Range of Cargo

Particularly suitable for transportation of heavy loads, sharp edged cargo, paper, steel sheets, chipboards, reinforcing steel mesh, palletised loads, concrete panels, glass, concrete pipes and many other types of cargo. Also ideal for ute trays to stop tools and other materials moving around.

Cost Saving $$

Suitable mats can more than halve the number of lashings required to secure a load, which translates to cost savings as the load takes less time and fewer materials to secure. The load also has a higher chance of arriving at its destination safely. Mats reduce damage to the load as well as the transportation vehicles.

CARGO TOOLS:

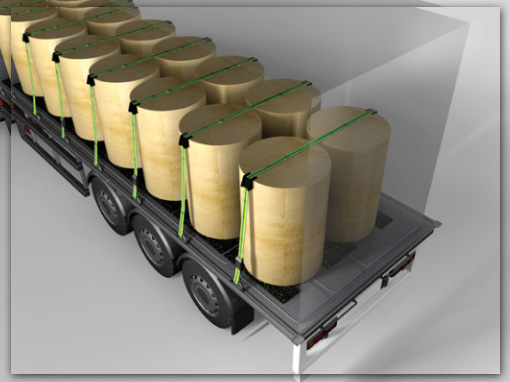

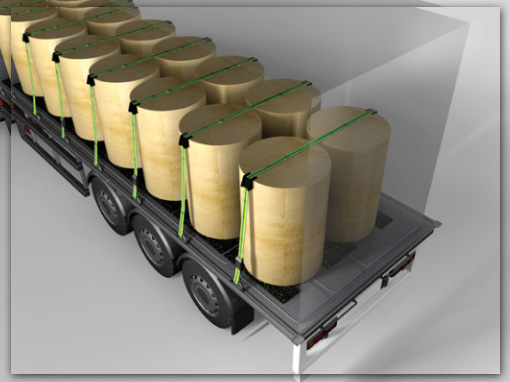

REGUPOL WEBBING PROTECTORS:

REGUPOL Webbing Protectors - Transportation

Cargo often has sharp edges that cause premature wear and tear on the lashings that are used to hold goods in place. This is where webbing protectors come in, as they act as a buffer between the cargo and the lashing straps. They also play an important role in protecting breakable goods from damage.

When REGUPOL webbing protectors are in use, the lashing straps slide across the load (on both edges) when being lashed, which results in an even distribution of the belt’s lashing capacity. The webbing protectors consist of a robust, anti-slip material on the underside, with a special fabric layer to the upper side.

Material

- Material: Robust, friction-enhancing and pressure-resistant REGUPOL anti-slip material with a special fabric on the upper side

Advantages

- Flexible and optimally adaptable for all lashes.

- Fast, simple fixing.

- No threading of the lash required.

- Improvement of the transfer coefficient K.

- Rear side – original Regupol anti-slip mats.

EASY APPLICATION: fit protectors in a few simple moves

REGUPOL TRANSPORT MATS

A reliable & indispensable component for professional load securing systems!

FAQs:

Read through some of the most commonly asked questions we receive when clients enquire about REGPOL Load Restraint Transport Mats

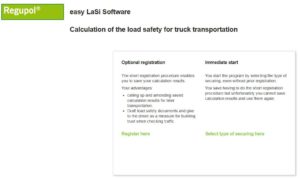

LOAD SAFETY CALCULATION:

Regupol offer a free online calculation tool to calculate load safety (no software download required). Simply click the link below and follow the steps.

GENUINE REGUPOL: Colour Coding

The way to recognise genuine REGUPOL anti-slip mats is easy: they have a distinctive and legally protected colour coding:

LOOK FOR THE YELLOW & GREEN PARTICLES

INADEQUATELY SECURED LOADS

Read about the dangers of inadequately secured loads and acceleration forces during transport.

http://www.flooringunderlay.com.au/

CALCULATE LOAD SAFETY (free online tool)

Use the FREE load safety calculation software (no download required)

http://www.regupol-easycargosec.eu/

REGUPOL ANTI-SLIP SLIP MATS ARE TESTED BY:

Request a Free Sample of Rubber Load Restraint Matting

Contact us to receive a free sample swatch of load restraint matting, containing REGUPOL Cargo Mat 7210, REGUPOL Cargo Mat 9510 and REGUPOL Cargo Mat 1000

Product Enquiry Form

BESPOKE SOLUTIONS

LATEST NEWS

Address: 14B Port Kembla Drive, Bibra Lake

WA, 6163

Call: +61 8 9314 4000

Email: [email protected]

Business Hours: 7am-4pm Mon-Fri

GOOGLE MAP

COLOUR DISCLAIMER: Product colours should be used as a guide only. Actual product colours can vary from the colour on your screen due to variations in monitor displays.

CONTENT DISCLAIMER: ABS West has taken all reasonable care in producing the content contained in this website. However, ABS West will not be responsible to loss or damage arising from the use of this information. The contents of this website should not be used as a substitute to detailed analysis or investigations regarding product information, or any queries the reader wishes to have answered.